Stripper II

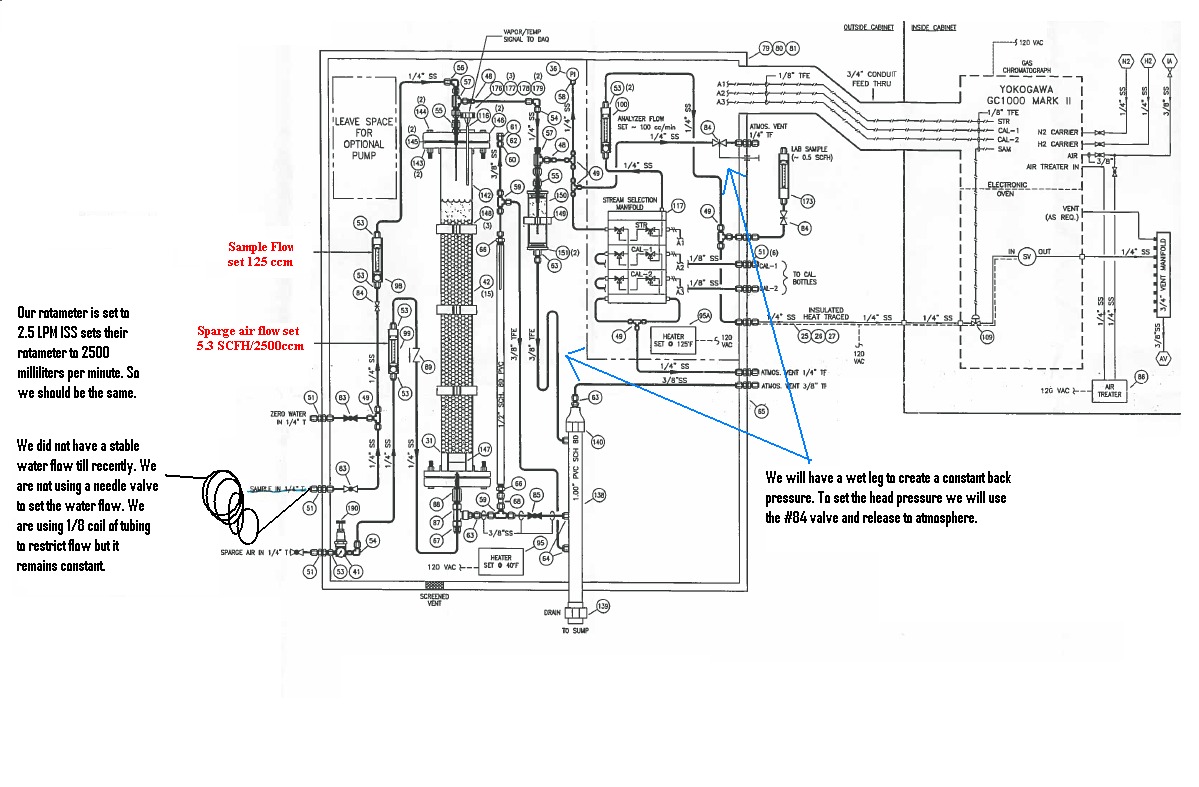

On this stripper we take 3/8" poly tubing and it goes down and then curves back up and this holds a wet leg. This wet leg creates the backpressure to force the sample to the analyzer and thus filling our sample valves with fresh sample.

Each morning the analyzer will run a validation with a known standard. It will run three runs and must be within a certain tolerance or it will fail. After these three runs we will return to measuring process. What happens if the wet leg is gone? Well, cal gas remains in the sample valve and process will simply go out the tube that used to have the wet leg. So we will be seeing cal gas on process for an extended period of time and it really pisses people off with alarms. Makes us look like we are pouring chemicals into the cooling tower.

Each morning the analyzer will run a validation with a known standard. It will run three runs and must be within a certain tolerance or it will fail. After these three runs we will return to measuring process. What happens if the wet leg is gone? Well, cal gas remains in the sample valve and process will simply go out the tube that used to have the wet leg. So we will be seeing cal gas on process for an extended period of time and it really pisses people off with alarms. Makes us look like we are pouring chemicals into the cooling tower.

Siemens came out with the sparger and it is an awesome alternative to the stripper. The same principles apply. We will feed in a certain flow of cooling tower water and a certain rate of sparge gas. In this case they are using He. The gas and hydrocarbons are sent to the analyzer due to the back pressure created from the glass tube going over and down into the second glass overflow container. Water will fill up this second container and then overflow out and to a catch basin. Then returned to the cooling tower. That back pressure forces everything to the analyzer except for some tiny amount is pushed out the bottom of the glass tube.

Why is using He a very bad choice of sparge gas?

Cause they ain't making any more of it and when it's gone........ It's gone.

Watch us figure out it cures cancer right about the time we have used all of it up on earth.

______________________________